“We deliver high profile special projects across the globe.”

Harris Machine Tools has taken on the challenge of designing, building, delivering and commissioning global industry customizable solutions. Our customers come to us not only looking for high quality machines and equipment, but technical expertise.

We help them solve the machining, manufacturing, fabrication, and production challenges they are facing with the opening of new facilities, as well as upgrading and improving existing operations with innovative technologies.

Some of our client stories:

Monorail Wash / Paint Processing Line

Designed and installed a unique system for washing and painting large tanks by lifting and rotating them while simultaneously moving them from one operation to the next on a closed loop monorail system. The system allows them to keep each of the processing stations active at all times, improves washing and painting efficiency and coverage, and reduces processing time over their previous methods.

- Custom Closed-Loop Monorail System

- Two sets of Lift & Rotate units (10,000 lb. load capacity per set)

- Hydraulically actuated and synchronized lift system with safety stop pins

- Servo motor and slewing bearing for tank rotation

- Powered trolleys for moving tanks along monorail

- Unique coupling system to attach to tanks

Pipeline Growing Line System

Designed and installed a welding fit-up and growing line system for an international company building large diameter water pipelines in a developing nation. The system was designed to increase their productivity of the pipeline sections and fit into their existing fabrication facility without incurring a costly expansion of the facility.

- Hydraulic Fit-up style 30 ton turning rolls for welding short sections of pipe

- Automatic welding manipulator on rail system to weld short pipeline sections

- 40 ton welding turning rolls on rail system for welding the shorter pipe sections into longer sections

- Second automatic welding manipulator on rail system for welding the growing pipeline sections

Galvanized Pole Processing System

Designed, delivered, and installed a complete factory system for the automated processing of long galvanized steel poles. The system consists of a set of automated conveyors to transfer the poles between stations. At each station there is a set of turning rolls with hydraulic lift mechanisms to lift the poles from the conveyors and turn them for processing. The turning rolls are on rails to adjust their distance to handle different length poles. This system increased throughput by automating the transfer of the poles between processing stations, and automating the lifting and turning requirements for the poles at each of the processing stations.

- Custom pole conveyor system with safety stops

- Four sets of turning rolls on rails system, one set per processing station

- Hydraulically actuated and synchronized lift system on turning rolls

- Uniquely designed transfer carts capable of carrying multiple poles

- Powered cart with turning rolls for blast booth operation

- Individual control consoles for each processing station

Need a Customized Solution?

Our Featured Brands

Steady-Weld

Steady-Weld offers a full line of high quality welding positioning equipment.

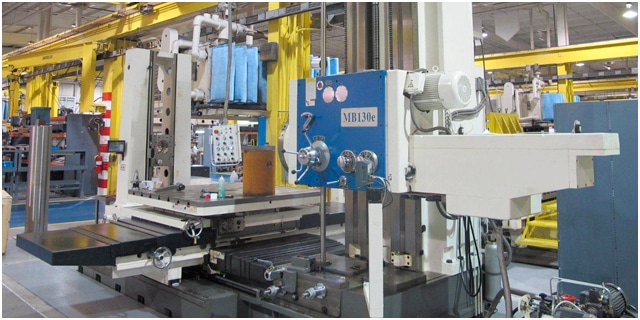

Knuth

World renowned German manufacturer of precision CNC and Conventional machine tools.