Please call us for a Quote or Information on these Conventional Horizontal Boring Mills

(713) 462-5800

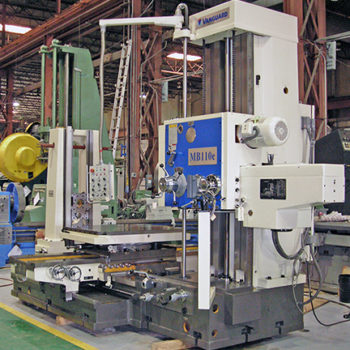

The MB110e (4″) and MB130e (5″) Conventional Table Type Horizontal Boring Mills are used to mill, drill, bore, face, groove, etc. all types of steel and alloy components. These machines consist of 100% heavy duty cast iron construction for superior vibration damping and cutting accuracy. They feature a built in rotary table for machining four sides of a complex part in a single set up. They also have a built in facing head for expanded functionality. A heavy duty outboard support is optional for completing highly accurate line boring. Newall DRO’s are installed on the X, Y and Z axes for highly accurate machining.

MB110e 4″ Conventional Horizontal Boring Mill

Spindle dia.: 110 mm (4.33″) / ISO 50 Taper

Spindle speeds: 9 – 1000 rpm / 10 HP spindle motor

Facing head speeds: 6 – 221 rpm

Table size:1100 x 1200 mm (43.3″ x 47.2″) / 4000 kg (8800 lbs.) load cap.

Travels: X 63″/ Y 55.1″/ Z 55.1″ / W 23.6″ / U 6.7″ / B 360°

MB130e 5″ Conventional Horizontal Boring Mill

Spindle dia.: 130 mm (5.11″) / ISO 50 Taper

Spindle speeds: 8 – 900 rpm / 20 HP spindle motor

Facing head speeds: 5.4 – 140 rpm

Table size: 1600 x 1800 mm (63″ x 70.8″) / 10,000 kg (22,000 lbs.) load cap.

Travels: X 78.7″/ Y 78.7″/ Z 74.8″ / W 35.4″ / U 7.8″ / B 360°